Here you will find the most common questions related to natural slate and our selection of products.

Frequently asked questions

THERMOSLATE

1. General

The thermal solar panels use solar radiation to produce energy which can be used to produce hot water, control swimming pool temperatures or central heating.

- Thermal solar energy uses space more efficiently than photovoltaic energy.

- The panels are smaller and have an average efficiency of over 70% compared to the 10-25% produced with photovoltaic.

- It can generate hot water, control swimming pool temperature or central heating. It does not generate electricity.

- It is not subject to special taxes.

Yes, by replacing part of the previously installed slate with THERMOSLATE panels. For aesthetic reasons, it is necessary for the slate format of the roof to match the slate used in THERMOSLATE. This means that the slate is of the same format and quarry, and is installed with the same overlap.

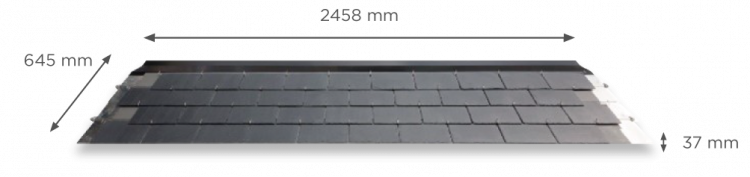

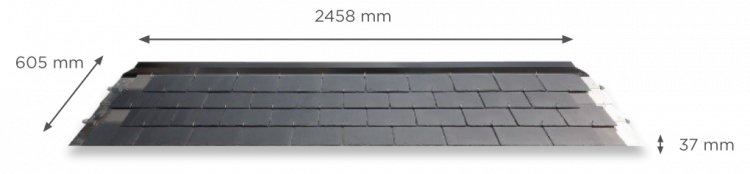

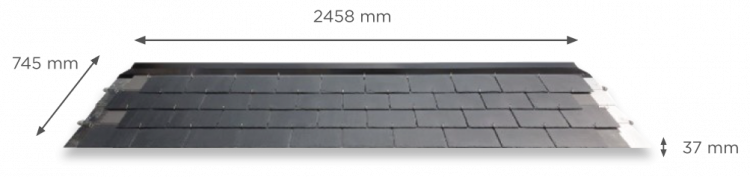

They have standard sizes:

- THS 3222.S07 (hook) 2458x645x37 mm Spain

- THS 3222.S10 (hook) 2458x605x37 mm France

- THS 5025.S10 (nail) 2267x743x37 mm Great Britain

- THS 4022.S11 (hook) 2458x745x37 mm Belgium

- THS 4020.P (flat) 1200x800x35 mm

No, it doesn’t. THERMOSLATE is a thermal solar panel not photovoltaic. It generates energy to produce hot water, control swimming pool temperature or central heating.

THERMOSLATE panels can be installed on sloping roofs. The panels are always hidden and perfectly integrated with the natural slate.

THERMOSLATE panels should be installed by the slate roofer in charge of the project and a plumber will need to carry out a water tightness test to ensure the installation is working properly.

The first THERMOSLATE installation was in 2008.

Yes, the majority of the panel is composed of: (1) slate, (2) aluminum and (3) XPS. All three of these materials can be recycled.

2. Compatibilities

No, because these panels work by taking advantage of the natural characteristics of slate (its color and thickness) which transmit the captured heat to the absorber.

No, it has to be CUPA PIZARRAS slate, as this has been tested and certified.

No, THERMOSLATE is only produced in a rectangular format. The following formations do not allow a complete integration or water tightness; Pico Pala, Redonda, Rombo, Granel, Media Luna and Shuppen.

It is compatible with radiant flooring systems or low-temperature convectors (radiators of 45-60°C).

Yes, in principle there should be no problem. This answer should be confirmed by the battery manufacturer.

The solar panels will not overheat due to the intrinsic properties of the slate which dissipate the heat. No action is needed thereon.

Drain-back systems are used exclusively with solar collectors that, due to their design features, are capable of producing gas in the primary circuit due to overheating. It is feasible for it to be installed with any type of collector, however, due to its design features, Thermoslate does not reach dangerous temperatures that make the use of drain-back necessary.

3. Profitability And Performance

Our THERMOSLATE rates include both the collector and the rest of the components necessary for installation, including fixing and integration accessories, as well as waterproofing.

It depends on the geographical location of the residence, the orientation and slope of the roof, as well as on energy needs.

To get an idea of how many panels a building needs and their amortization period, we calculate the installation requirements for each project using the T-SOL calculation program.

For example, in our general product catalog we showcase a residence in the French Pyrenees. With a useful life of 25 years, it is estimated that the owners of this house will amortize their investment in thermal panels in just 10 years.

The main advantages of THERMOSLATE are its aesthetics (complete integration into the roof), its durability (slate) and its need for zero maintenance. THERMOSLATE has a similar investment-to-energy production ratio to other standard collectors on the market. In other words, with a similar investment, similar annual energy yields are obtained.

THERMOSLATE is not a photovoltaic panel.

The THERMOSLATE output is dependent on the geographical location of the building and characteristics in that area as well as the roof pitch. On average, the panels usually cover between 30-70% of the annual requirements.

Our engineers will assess the building taking into consideration any trees or objects blocking sunlight from the thermal solar panels. Any objects in the way will reduce the solar radiation and THERMOSLATE performance.

The system requires direct solar radiation therefore, if weather conditions limit this then the full efficiency won’t be reached.

4. Technical Questions

3.5-3.75 mm

It has to be the same in order for the collector to be integrated into the roof. Cupa 10 selection R10 Excellence.

Installation below 22º is not recommended. This is to guarantee that the roof is sufficiently watertight.

Yes. The installation is monitored by fitting a sensor in the lateral connection line between the insulator and the absorber of the highest collector in the array. Effective contact with the absorber must be ensured for it to function correctly.

The temperature difference is 3ºC.

No, the sensor is placed between the insulator and the absorber of the highest panel of the array.

Yes. T-SOL software takes into account all existing thermal losses in each section and component of the solar installation.

- THS.3222.S07 collector = 11.53 W/m²K

- THS.3222.S10 and THS.4022.S11 collectors = 13.55 W/m²K

- TH3222.S07 collector = 0.82

- TH3222.S10 and THS.4022.S11 collectors = 0.86

This is not necessary, because it has the same temperature as the collector. There is a maximum of 90ºC, and no possible losses. Meanwhile, the other pipes (hot and cold water pipes) and the collector inlets and outlets must be insulated. Armaflex is an insulation brand we recommend.

50 liters of DHW per day in conditions of average exposure and solar radiation, and with a 45º slope. A project-specific solar study needs to be conducted in order to find out the exact answer.

Thermally conductive resin.

It is always advisable to install a small expansion vessel to protect the tank. In Spain, it is compulsory according to RITE installation regulations. However, the expansion vessel depends on the tank and not on the THERMOSLATE collection system.

The recommended design flow rate for the THERMOSLATE collector is between 42-84 (l/h m²).

The software we work with (T-SOL) uses a calculation flow rate of 60 (l/h) m2 per collector surface. To find the total flow rate for all panels, simply multiply this flow rate by the number of panels.

The recommended pressure is 2-4 bar, not exceeding a maximum pressure of 6 bar.

This depends on the design flow rate of the installation:

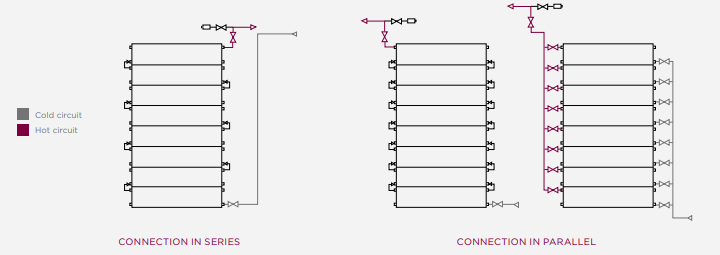

Flow rate of 30 l/h m² for connection of collector batteries connected in series:

| Collectors number | Pipe diameter (mm) |

|---|---|

| 1-4 | 12 |

| 5-8 | 14 |

Flow rate of 60 l/h (m²) for connection of collector batteries connected in parallel:

| Collectors number | Pipe diameter (mm) |

|---|---|

| 1-4 | 14 |

| 5-8 | 18 |

| 9-12 | 20 |

THERMOSLATE can be connected in series or in parallel, forming arrays. The number of collectors connected will depend on the conditions and location of installation.

The collector surface area can be multiplied by connecting collector batteries in parallel. This type of connection increases the system’s final output. Where feasible, Cupa Pizarras recommends the parallel installation of arrays of 4 or 6 modules.

The hydraulic balance of the complete system can be achieved in two ways:

- Balancing valves.

- Connecting arrays with the same number of collectors and using the inverted return pipe design.

The collector allows maximum positive wind and snow loads equivalent to 0.3 MPa.

The maximum negative wind load allowed by the collector is 3.6 KPa.

The necessary space is calculated according to the width of the slate pieces and the thickness of the hook used. Below is a simple rule to correctly define the separation space:

- For panels 3222.S07 and THS.3522.S10, it is calculated using the formula: D = 223 x N / D ≥ 670 mm

- For panels 3222.S10 and THS.4022.S11, it is calculated using the formula:

D = 225 x N / D ≥ 675 mm

- For the panel 5025.S11, it is calculated using the formula: D = 250 x N / D ≥ 750 mm

N = Number of slates

CUPA PIZARRAS does not recommend defining a minimum separation between arrays in parallel of less than the distance required for the installation of 3 pieces of slate. Using a smaller distance between the arrays may cause difficulties during installation, and could compromise the strength of the slate in the integration zone.

Yes, they are necessary. They are placed at the inlet and outlet of each panel array to isolate the array from the rest of the installation in case of breakdown or maintenance.

Yes, it is necessary for air extraction. It is placed at each outlet of a THERMOSLATE panel array.

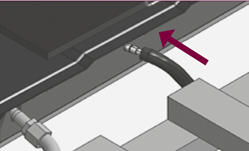

The recommendation is to install an extendable anti-vibration hose at the inlet and outlet of each array to absorb any possible thermal expansion.

The entry point of the primary circuit pipes to the area under the roof must be taken into account, so that there is no interference with the installed collectors from this point.

If it is a new build, the location of the drainpipes should be considered during the design phase in order to prevent problems during construction. The passage to the area under the roof must be completely sealed after installation is completed.

The system works properly at temperatures below 0°C. A mixture of water and glycol should be used inside the panel for this purpose. In our case, we market a heat transfer fluid (THS.ANTIFROGEN SOL) which allows the panels to operate at temperatures from -23°C to +200 °C.

On a sunny day, the system will operate at 40-45ºC above ambient temperature on average.

The glycol circulation system through the solar collectors is forced, meaning there is a pump which is regulated by a control unit, and starts or stops depending on the difference between the temperature of the collectors and the temperature of the tank. There are compact pumping units on the market that include all the necessary elements.

A pump that is capable of pumping 40 liters per hour per m² of panel installed.

5. Warranty period

CUPA PIZARRAS provides a TSV6.X warranty. Terms and conditions;

- Production defects which appear in the first 5 years after the original purchase of the product.

- Permeability and integration of the system on the roof; in the first 10 years after the original purchase of the product.

- Internal corrosion of the absorbers; in the first 5 years after the original purchase of the product.

THERMOSLATE does not require any maintenance. However, we advise customers to have an annual inspection to ensure no breakages and if necessary, cleaning of the roof.

5. Regulation

Yes. We belong to ASIT (Association of Solar Thermal Installations).

Yes, they are certified.

Thermoslate has the European Solar Keymark certificate and the French Avis Technique certificate.

This certificate is issued by ICIM, an Italian public body, which is authorized to issue certificates (AENOR type). This institution issues the Solar Keymark certificate on the basis of tests carried out by the Giordano Institute, in accordance with European standards EN 12975-1 and EN 12975-2.